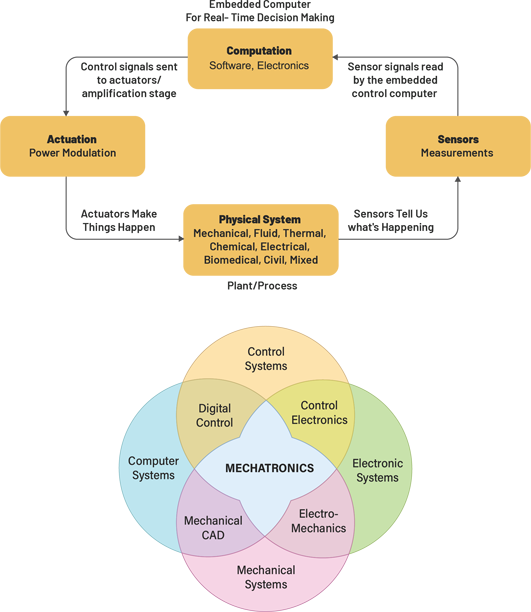

Mechatronic System Design refers to the synergistic integration of three distinct traditional engineering fields for system-level design processes:

- Mechanical engineering where the word “Mecha” is taken from,

- Electrical or electronics engineering, where “Tronics” is taken from,

- Computer science.

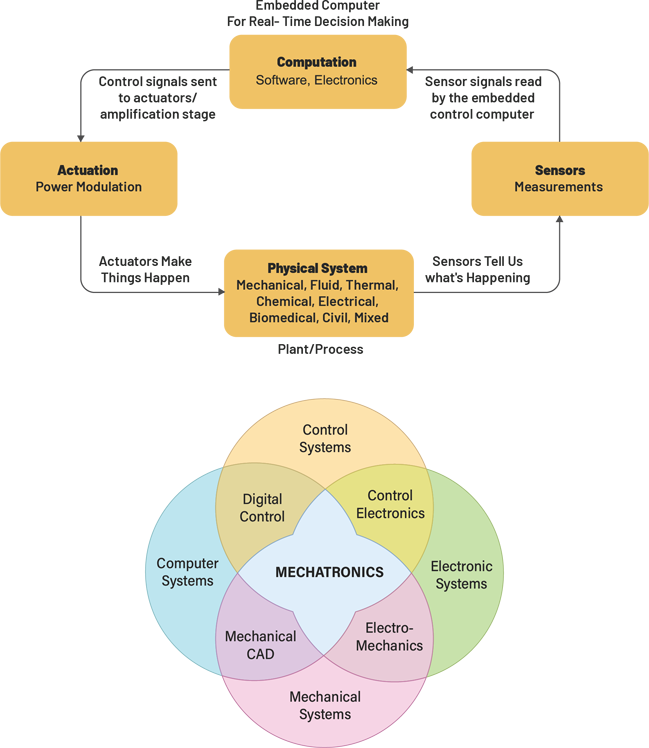

A mechatronic system is a computer-controlled mechanical system, where the computer is an embedded computer, not a general-purpose computer, that is used for control decisions, and interfaced to the real world device via sensors and actuator interfaces.

A mechatronic system has the following components:

- Mechanical system (i.e.EV power train)

- Control computer (i.e. ECU)

- Sensors (i.e. speed)

Mechatronic system design begins with the concept of mechanical system design that includes electrically controlled actuators, and sensors to measure variables that need to be controlled. Good design based on sound scientific and engineering principles forms the foundation of the overall quality of the system design. Computer control should always enhance the system capabilities, instead of trying to compensate for poor mechanical designs.

Mechatronic System Design refers to the synergistic integration of three distinct traditional engineering fields for system-level design processes:

- Mechanical engineering where the word “Mecha” is taken from,

- Electrical or electronics engineering, where “Tronics” is taken from,

- Computer science.

A mechatronic system is a computer-controlled mechanical system, where the computer is an embedded computer, not a general-purpose computer, that is used for control decisions, and interfaced to the real world device via sensors and actuator interfaces.

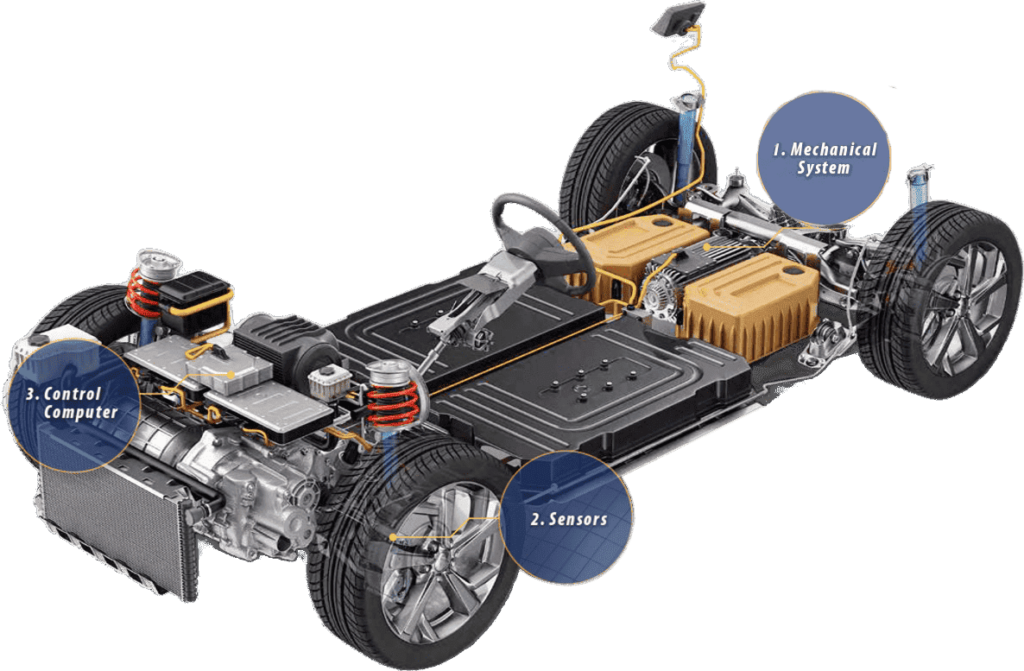

A mechatronic system has the following components:

- Mechanical system (i.e.EV power train)

- Control computer (i.e. ECU)

- Sensors (i.e. speed)

Mechatronic system design begins with the concept of mechanical system design that includes electrically controlled actuators, and sensors to measure variables that need to be controlled. Good design based on sound scientific and engineering principles forms the foundation of the overall quality of the system design. Computer control should always enhance the system capabilities, instead of trying to compensate for poor mechanical designs.

Mechatronic System Design refers to the synergistic integration of three distinct traditional engineering fields for system-level design processes:

- Mechanical engineering where the word “Mecha” is taken from,

- Electrical or electronics engineering, where “Tronics” is taken from,

- Computer science.

A mechatronic system is a computer-controlled mechanical system, where the computer is an embedded computer, not a general-purpose computer, that is used for control decisions, and interfaced to the real world device via sensors and actuator interfaces.

A mechatronic system has the following components:

- Mechanical system (i.e.EV power train)

- Control computer (i.e. ECU)

- Sensors (i.e. speed)

Once the hardware design is done, the next component of the system that defines its “brains” (intelligence) is the embedded software that goes into the ECU. Often, the ECU hardware, actuators, and sensors are standard off-the-shelf components. Software is always application-specific. Furthermore, as there is no limit on intelligence, then there is no limit on how “smart” and reliable we can design application software. It is common that over eighty percent of all mechatronic design engineering time is spent on software development.

Embedded software is different than general-purpose software in many different ways, even though they are both software; such as

Embedded software must run in real-time, andthere can be life-and-death consequences of a few seconds of delay.

Embedded software must be reliable as lives may be riding on it.

Embedded software has limited CPU and memory resources.

Because of these critical requirements, expertise, discipline, experience, and pureintellectual capabilities of the development team is the most critical element of product development.

A mechatronic system has the following components:

- Mechanical System (i.e.EV power train and actuators)

- Sensors (i.e. speed sensors)

- Control Computer (i.e. ECU)

Mechatronic system design begins with the concept of mechanical system design that includes electrically controlled actuators, and sensors to measure variables that need to be controlled. Good design based on sound scientific and engineering principles forms the foundation of the overall quality of the system design. Computer control should always enhance the system capabilities, instead of trying to compensate for poor mechanical designs.

Once the hardware design is done, the next component of the system that defines its “brains” (intelligence) is the embedded software that goes into the ECU. Often, the ECU hardware, actuators, and sensors are standard off-the-shelf components. Software is always application-specific. Further more, as there is no limit on intelligence, then there is no limit on how “smart” and reliable we can design application software. It is common that over eighty percent of all mechatronic design engineering time is spent on software development.

Embedded software is different than general-purpose software in many different ways even though they are both software

Embedded software must run in real-time, and there can be life-and-death consequences of a few seconds of delay.

Embedded software must be reliable as lives may be riding on it.

Embedded software has limited CPU and memory resources.

Because of these critical requirements, expertise, discipline, experience, and pure intellectual capabilities of the development team is the most critical element of product development.